- Have any questions?

- +1.604.207.0633

- info@aurorascicorp.com

The Largest DLC Coating System Installed during COVID

March 30, 2021This is the question often asked around the cutting tool user community when searching for the best coating for their tools or applications.

For a comprehensive understanding, let’s start with the basic building block of DLC, i.e., carbon. DLC stands for Diamond-Like Carbon, a sibling of diamond. They are both made from carbon atoms, but forms different bonding networks and structural configurations, and thus exhibit different looks and properties.

For a comprehensive understanding, let’s start with the basic building block of DLC, i.e., carbon. DLC stands for Diamond-Like Carbon, a sibling of diamond. They are both made from carbon atoms, but forms different bonding networks and structural configurations, and thus exhibit different looks and properties.

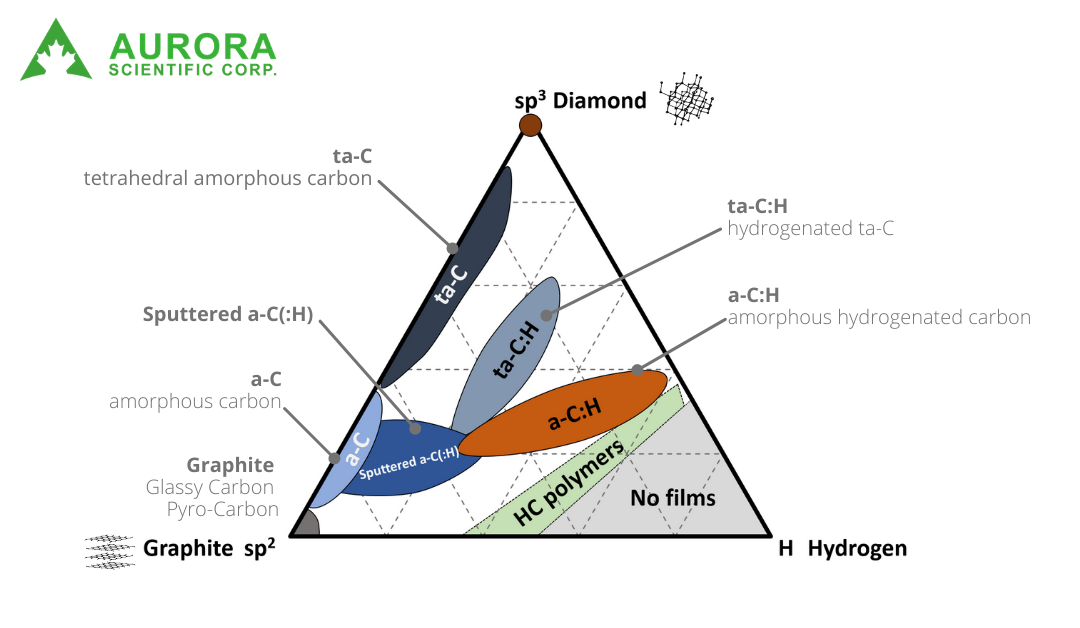

DLC has been around for more than 60 years. It is not new at all. It is a family of carbon materials that include:

- “a-C” when it is simply amorphous carbon

- “a-C:H” when you incorporate hydrogen into a-C

- “a-C:Me” when you incorporate a metal element into a-C

- “a-C:H:Me” when you dope metal to a-C:H

- “a-C:X” when you incorporate a non-metallic element (Si, O, F) to a-C

- “a-C:H:X” when you incorporate hydrogen into a-C:X

- “ta-C” when you synthesize a-C with a high ratio of sp3 carbon bonds

- “ta-C:H” when you incorporate hydrogen into ta-C

- “ta-C:X” when you incorporate a non-metallic element to ta-C”

Where does DLC coating shine?

DLC is great and chic, but not wonder. It has its pros and cons.Pros of DLC Coating

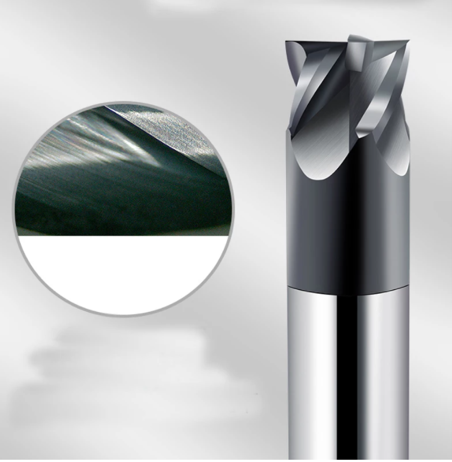

Armed with great hardness and a low coefficient of friction, DLC surpasses many conventional ceramic coatings (TiN , CrN, ZrN, and AlTiN) in applications such as metal machining and component protection in the automotive, aerospace, and medical industries. For example, in modern diesel engines, the high-pressure diesel injection system, tappets, and piston pins are coated almost exclusively with DLC today. Many manufacturing industries can also benefit from using DLC coating for enhanced performance of their cutting tools, molds, and dies.With the advent of using composite materials as advanced structural materials in modern aircraft and transportation systems, cutting tools can be coated with extremely high hardness and low friction DLC (e.g., ta-C) to tackle the extensive tool wear and work-piece damage issues.

Cons of DLC Coating

Aside from all those great mechanical and physical properties, DLC suffers from challenges of low heat tolerance and poor adhesion to metal or carbide substrates. DLC is not a suitable alternative to AlTiN or TiSiN coatings in higher working-temperature environments that require high hardness at high processing temperatures. Most DLC coatings start degrading at temperatures over 400˚C. Limited improvement of high-temperature stability can be done by altering the sp3/sp2 carbon bond ratio and the doping of Si to a-C:H. The research and development for more capable and enduring DLC are still in progress today.How to deposit DLC properly?

Since DLC comes in various chemical compositions and structures for specific functionality, it has been deposited by using many technologies such as PECVD, magnetron sputtering, laser-arc deposition, cathodic arc evaporation, etc.One of the key contributions to high-quality DLC is ion energy when depositing DLC coatings. Therefore, the cathodic arc plasma deposition technology, also a dominating modern PVD technology for cutting tools, leads the pack because of its high ionization-ratio plasma and the system flexibility for industrial volume production.

The Surftech STAR4 cathodic arc system operating at Aurora Scientific Corp. Canada uses the patented CAAD (cathodic arc activated deposition, US Patent No. 6,331,332B1 under Dr. Da-Yung Wang of Surftech Corp.) process to deliver DLC coatings to many tool manufacturers in North America. The CAAD managed the essential DLC-metal adhesion problem by in-situ deposition of a metallic interface and a series of metal to carbide transition layers to ensure the optimum film adhesion to either tool steel or carbide substrates.

The final DLC top functional layer is deposited by dissociation of acetylene precursor gas stimulated by a synchronized energetic metal plasma. The entire complex procedure is completed within the same STAR4 PVD system without any additional plasma source or batch interruption. The added advantage of the STAR series’ CAAD DLC deposition process is the ease of adding desire metal or non-metal dopants in-situ to further enhance individual properties of the super-hard and super-lubricious carbon films for modern applications.