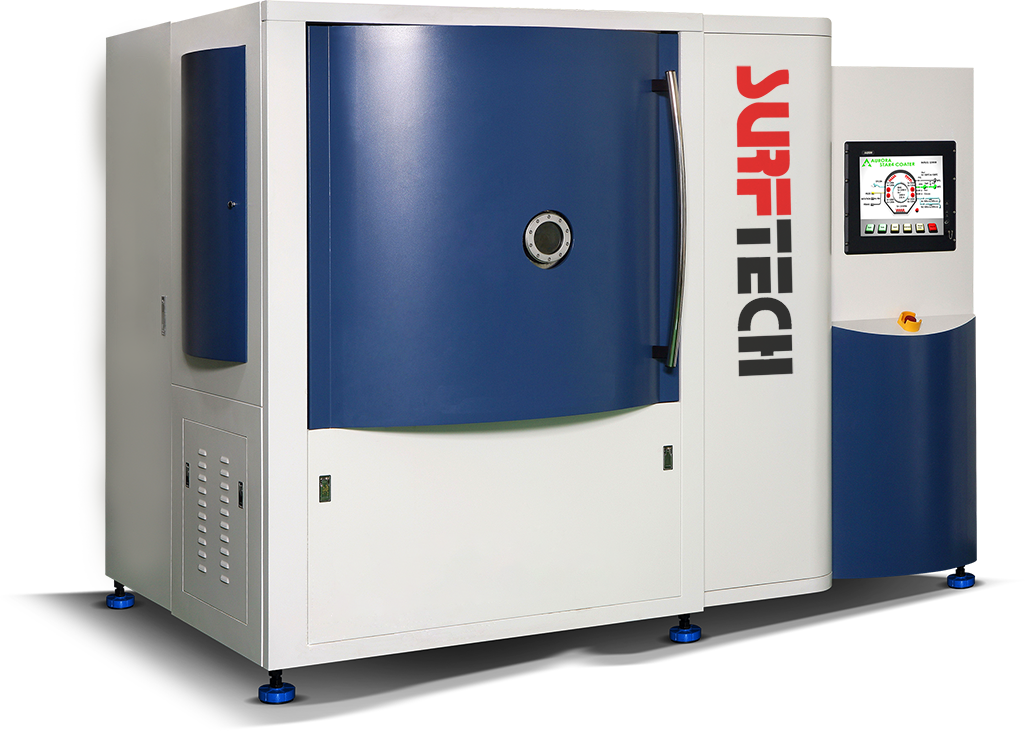

STAR-4 PVD Coating System

The STAR-4 is a high-capacity PVD coating system designed for medium-sized operation. The key features include fast cycle time, easy operation with a 5-axis planetary carousel, and six sets of Φ6" circular cathodic arc evaporators. STAR-4 is ideal for customers looking to expand in-house PVD coating capability and have the best return on investment (ROI).

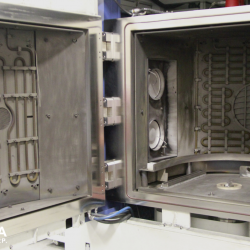

Vacuum Chamber

- Construction: 304 stainless steel with chamber shutter

- Cooling: Double walled chamber with water cooling

- Chamber Size: Φ 850 × 800 mm (Φ 33.5” x 31.5”)

- Effective Plasma Zone: Φ 580 × 550 mm (Φ 22.8” x 21.6”)

Cathodic Arc Evaporation Source

- Cathode: 6 sets of Φ6" circular cathodic arc evaporator/ Auto arc triggering

- Power Supply: 6 sets of 200A pulse DC power supply (Huttinger German made or equivalent)

- Water Cooling: 1 spare set of cathode cooling base

Pump System

- Primary Mechanical Pump: 65 m3/h (Leybold German made or equivalent)

- Root Pump: 250 m3/h (Leybold German made or equivalent)

- Turbomolecular Pump: 1600 l/s (Leybold German made or equivalent)

- Vacuum gate valve: Vacuum valves (Leybold German made or equivalent)

- Dust Filter: Filter for vacuum route (MANN German made or equivalent)

Vacuum Measure & Component

- Piezo Gauge: 1 set

- Pirani Gauge: 2 set

- Penning Gauge: 1 set

- Baratron Gauge: 1 set

Tools Per Batch

1360+

Based on ø 1/4” x 3” OAL

Coating Types

10+

Runs Per Day

4

Gas Flow Control

- Mass Flow Controller Ar & N: 1 set

- Mass Flow Controller C, H: 1 set

- Reactive Gas Filter & Valve : 1 set

Heater

- Heater Specification: 18kW 3 sets (chamber sides and door)

- Controller: 1 set of PID temperature control / 2 sets of thermocouple

Software Function

- User-friendly interface with touch screen control

- Password protected coating parameter input

- Automatic and manual process control

- Coating log and record & Self-monitoring

- Uninterruptible power supply (UPS) for Controller

- SIKA water flow sensor

- Remote diagnostics

- Safety interlock protect function

Cycle Time

- Batch Cycle Time: 4-5 Hours

Equipment Footprint

- Footprint: L 2500 x W 1850 x H 2200 mm (L 98.5” x W 72.8” x H 86.6”)

- Recommended Operating Footprint: L 5000 × W 5000 mm (16’ x 16’)

Loading Carousel

- Carousel: 2 sets of carousel & loading wagon

- Carousel Configuration: 5-axis planetary carousel

- Loading Capacity – Weight: 500 kg

- Loading Capacity - Space: Φ580 × 550 mm

- Plates – 17 slots (with 4-in-1 holder): ø 1/8" - ø 1/4" (or ø 3 - ø 6 mm)

- Plates – 25 slots: ø 5/16" - ø 1/2" (or ø 8 - ø 12 mm)

- Plates – 17 slots: ø 3/4" - ø 1" (or ø 20 - ø 25 mm)

Carousel Loading Capacity

- Regular Round Cutting Tool: ø 1/2” x 3” OAL - 500 pcs

- Small Round Cutting Tool:ø 1/4” x 3” OAL - 1,360 pcs

- Long Round Cutting Tool: Up to 10” OAL - 170 pcs