Firearm Finishes Compared: Aurora’s PVD vs. Cerakote, Parkerizing, Nitriding & Chrome

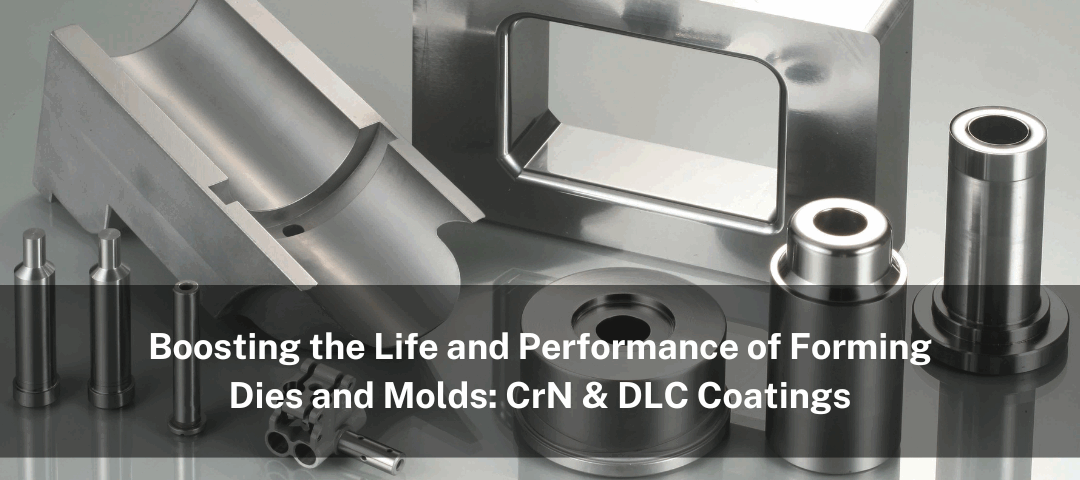

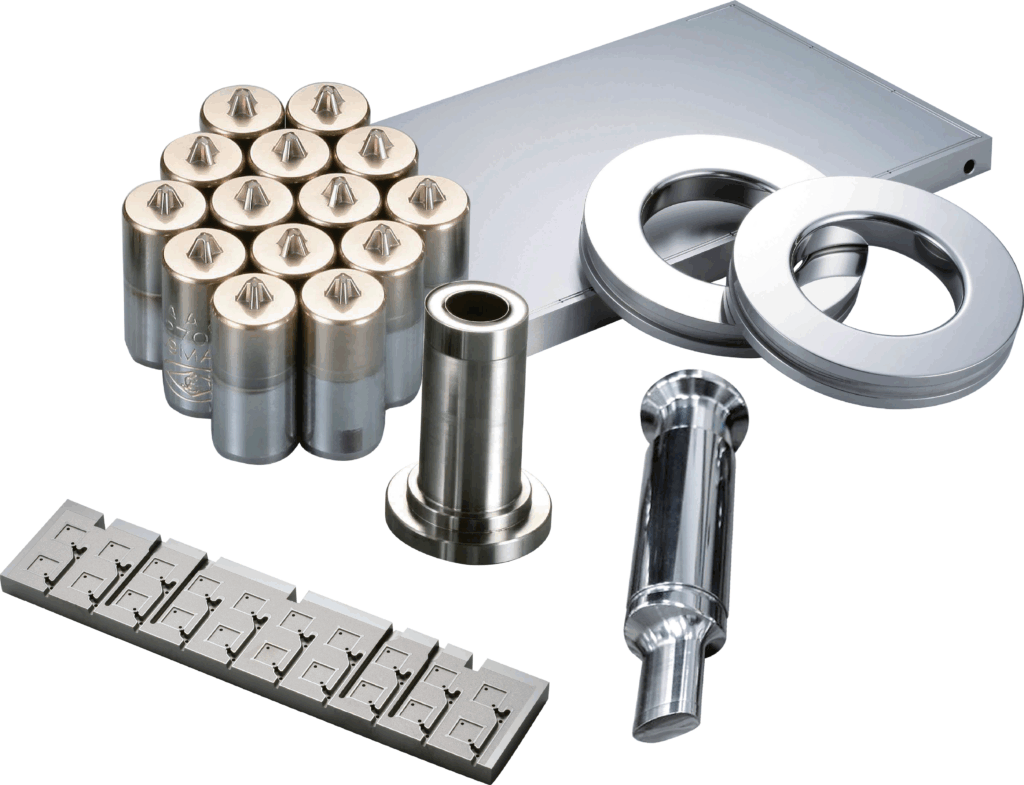

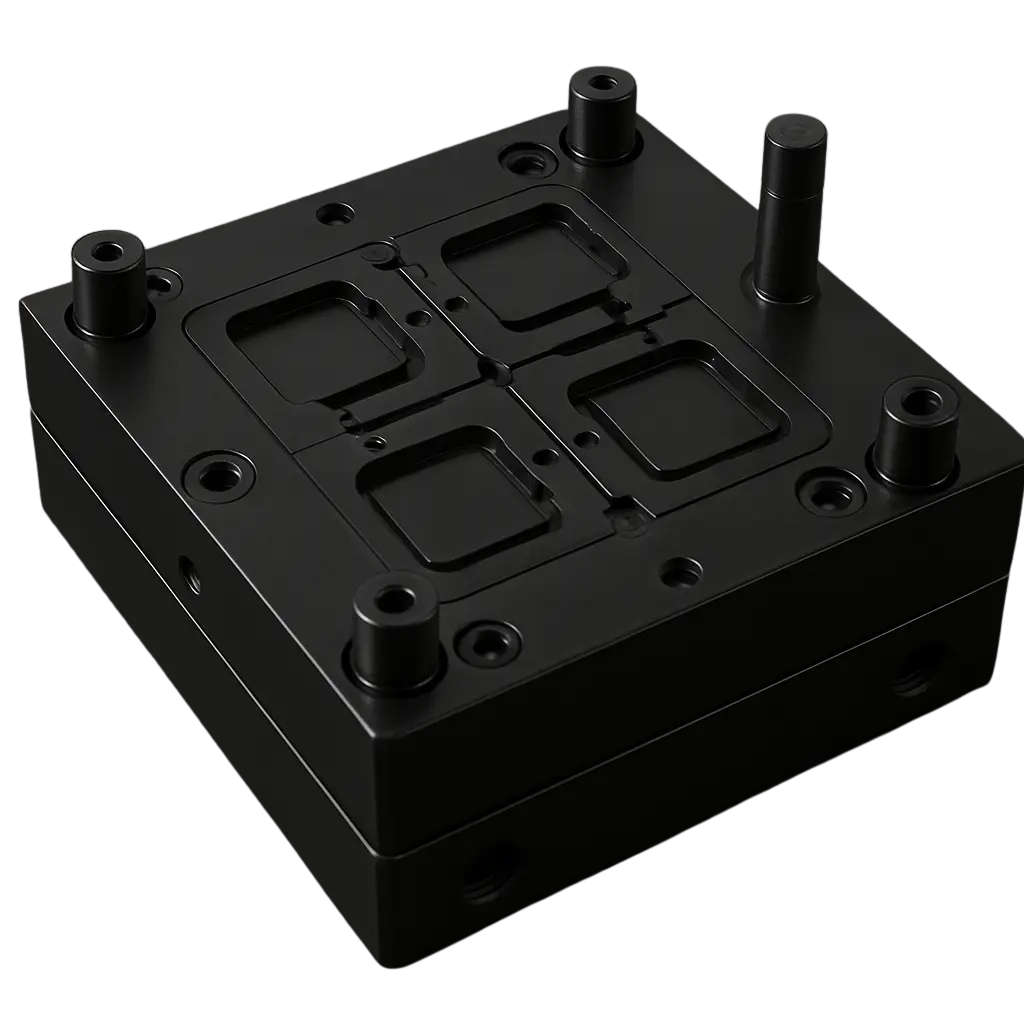

June 10, 2025Forming dies and molds are the backbone of manufacturing — shaping metals and plastics into the parts we rely on every day. But in production, these dies and molds face tough enemies: friction, heat, and wear. Over time, these factors can shorten tool life, lower product quality, and increase costs.

The solution? Advanced PVD coatings like CrN (Chromium Nitride) and DLC (Diamond-Like Carbon), which can dramatically extend die and mold life, improve part quality, and reduce maintenance.

Why Forming Die & Mold Wear Is Different from Cutting Tool Wear

In forming dies and molds, wear mechanisms differ from those in cutting tools because of the distinct nature of their interactions with the workpiece.

Forming dies and molds work mainly through sliding and compressive contact with materials.

This leads to:

- Adhesive wear (like galling and sticking)

- Fatigue wear

- Chemical or corrosion wear

Cutting tools, on the other hand, handle high-speed material removal, resulting in:

- Abrasive wear

- Diffusion and oxidation wear

- Notching and extreme heat at the cutting edge

In short: forming dies and molds need coatings that combat sliding friction and deformation fatigue, not just high-temperature abrasion.

What Are CrN and DLC Coatings?

Chromium Nitride (CrN) and Diamond-Like Carbon (DLC) are two widely used PVD coatings in forming dies and molds.

These coatings can be applied individually or together for maximum performance.

CrN (Chromium Nitride)

- Tough and durable

- Resists corrosion

- Low adhesion—reduces galling and sticking

DLC (Diamond-Like Carbon)

- Extremely hard

- Ultra-low friction

- Helps parts release from the mold more easily

Key Benefits of CrN/DLC PVD Coatings for Forming Dies and Molds

PVD (Physical Vapor Deposition) is used to apply thin, hard, and smooth CrN or DLC coatings to mold surfaces. Here's how they help:

Reduced Wear

The added hardness protects the mold surface from abrasive damage and prolongs its lifespan.

Lower Friction

DLC in particular offers very low friction, reducing sticking and making part ejection smoother.

Better Surface Finish

Low-friction coatings create cleaner, more precise molded parts with less surface defect.

Corrosion Resistance

CrN acts as a shield against moisture, chemicals, and oxidation—perfect for harsh environments.

Improved Productivity

With fewer breakdowns and less maintenance, manufacturers can reduce downtime and costs.

Eco-Friendly

Less friction means less need for lubricants—supporting cleaner, more sustainable manufacturing.

Why Choose Aurora Scientific Corp for Dies and Mold Coatings?

At Aurora Scientific Corp, we specialize in CrN and DLC PVD coatings designed for forming dies and molds.

Our advantages:

● Advanced PVD systems for precision application

● Proprietary coating recipes for superior adhesion and smoothness

● Consistent quality across complex mold geometries

● Proven results: longer mold life, reduced friction, and lower operating costs

Upgrade Your Forming Dies and Molds Today

If you’re ready to improve die and mold performance, extend tool life, and cut costs, Aurora Scientific Corp can help. Contact us below to learn how our CrN/DLC coatings can transform your manufacturing process.

Contact Us

Forming dies and molds are the backbone of manufacturing — shaping metals and plastics into the parts we rely on every day. But in production, these dies and molds face tough enemies: friction, heat, and wear. Over time, these factors can shorten tool life, lower product quality, and increase costs.

The solution? Advanced PVD coatings like CrN (Chromium Nitride) and DLC (Diamond-Like Carbon), which can dramatically extend die and mold life, improve part quality, and reduce maintenance.