Unveiling the Benefits of Corrosion-Resistant PVD Coatings

June 10, 2024

Elevate Your cutting Tools with Air Lapping System: All-in-One Edge-Prep, Polishing and Deburring

August 29, 2024Surviving the Elements:

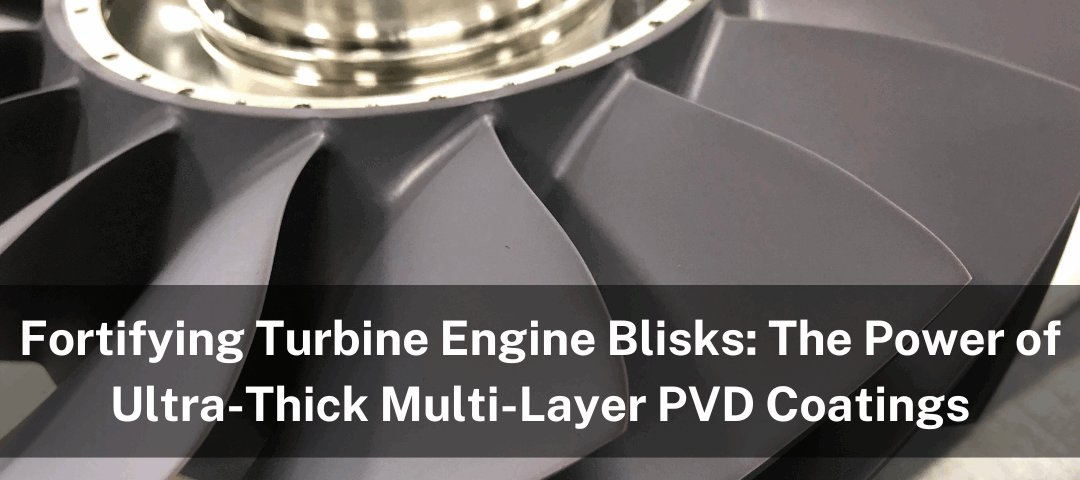

In many industries, equipment and components are constantly battling harsh environments filled with moisture and abrasive particles. This leads to erosion—a destructive combination of corrosion and wear—that eats away at materials, causing surface damage and drastically shortening the lifespan of crucial components. Imagine the blades in a turbine engine’s compression compartment being bombarded by sand, dust, and hard particles from the air intake. It’s a battle that’s hard to win, but not impossible. Researchers have been hard at work developing advanced surface modifications to enhance erosion resistance, and PVD (Physical Vapor Deposition) technology has emerged as a game-changer.

Tackling Tough Challenges:

Hard coatings like transition metal nitrides (think CrN) are at the forefront of erosion protection. Yet, these coatings face a major hurdle: as they get thicker, they also get more stressed, leading to the dreaded coating spallation. Moreover, PVD technology’s line-of-sight process can cause an uneven coating buildup, especially on the sharp edges of curved blades. This results in increased stress and a higher chance of the coating peeling off. So, how do we overcome these challenges?

Innovative Solutions:

The solution lies in developing coatings that are not only hard, but also resilient to stress and spallation. This requires specially designed fixtures and masking techniques, alongside optimized coating parameters, to ensure even deposition and residual stress reduction. Additionally, implementing a multilayer design can further reduce stress while allowing for thicker coatings.

Aurora's Breakthrough

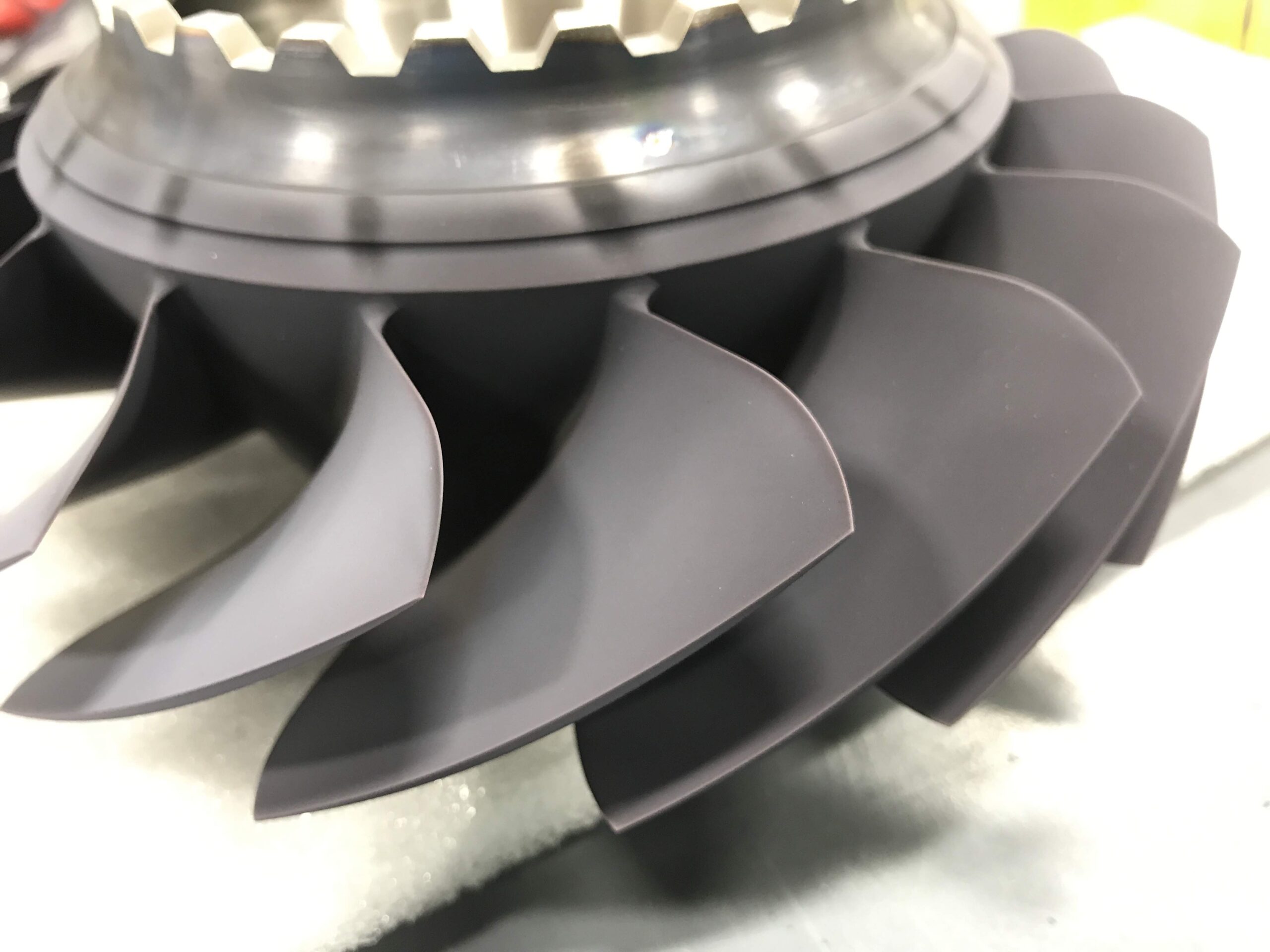

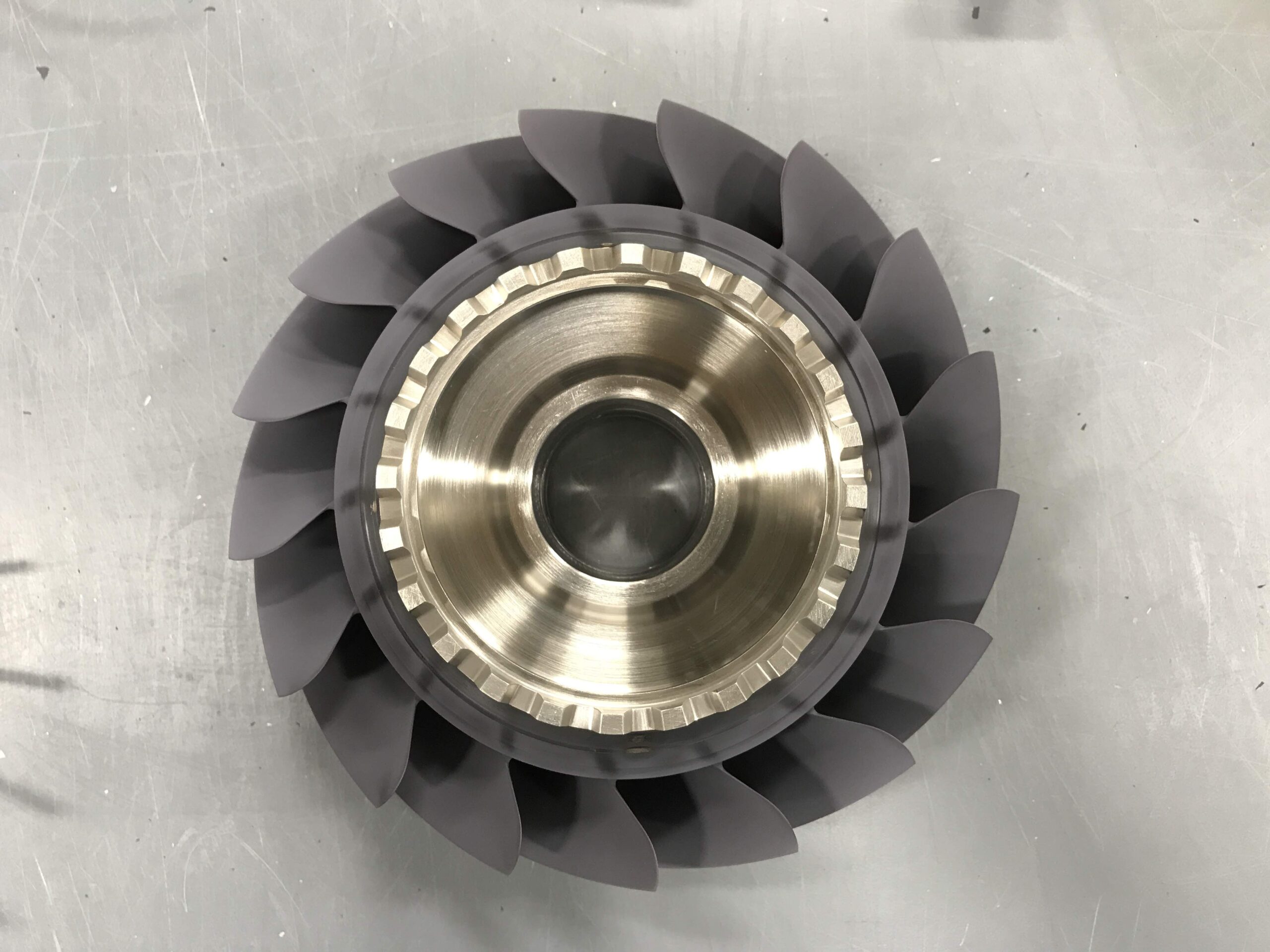

Aurora has risen to this challenge with groundbreaking TiN-based coatings infused with aluminum and chromium. By working together with Aerospace Research Center at National Research Council of Canada (NRC), our team’s innovative approach has resulted in thick, resilient coatings that are nearly impervious to erosion. We have successfully applied these advanced coatings on turbine impeller blades, achieving exceptional performance against erosion and excelling in the salt spray corrosion test (ASTM B117).

The Future of Turbine Engines:

Aurora’s advancements in PVD coatings are set to revolutionize turbine engine durability and performance. With our innovative solutions, turbine engines can now withstand the toughest environments, ensuring they remain robust, efficient, and ready for whatever comes their way.

Dive into the future of turbine technology with Aurora’s ultra-thick multi-layer PVD coatings and discover how we’re turning the tide in the battle against erosion.

Contact Us