Choosing the Right Surface Treatment: A Comprehensive Comparison

February 25, 2025

Firearm Finishes Compared: Aurora’s PVD vs. Cerakote, Parkerizing, Nitriding & Chrome

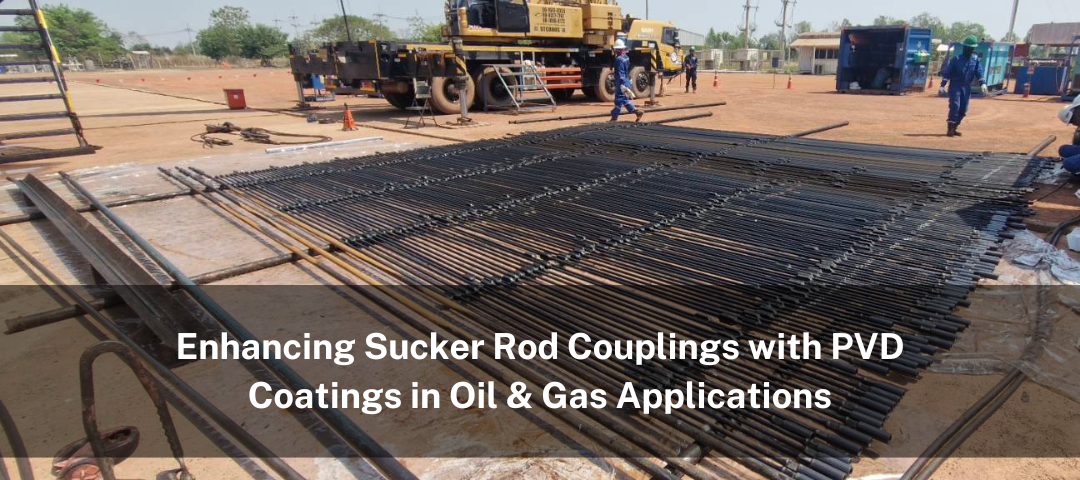

June 10, 2025Sucker rods and couplings are essential components of artificial lift systems, particularly in rod pumping systems used in oil and gas wells. They play a crucial role in lifting crude oil from the reservoir to the surface. Couplings are threaded connectors used to join individual sucker rods into a continuous rod string.

In rod pumping systems, couplings must withstand high loads, wear, corrosion, and fatigue due to continuous reciprocating motion. These components are subjected to mechanical stress, friction, and corrosive environments, which significantly affect their performance and longevity. Wear in the corrosive environment is the most common failure mechanism that reduces the service life of couplings and the overall rod pumping system.

Wear occurs due to constant contact of couplings with the tubing in the repetitive motion. Especially, in corrosive well conditions, this wear is accelerated, leading to rapid material degradation and potential system failure.

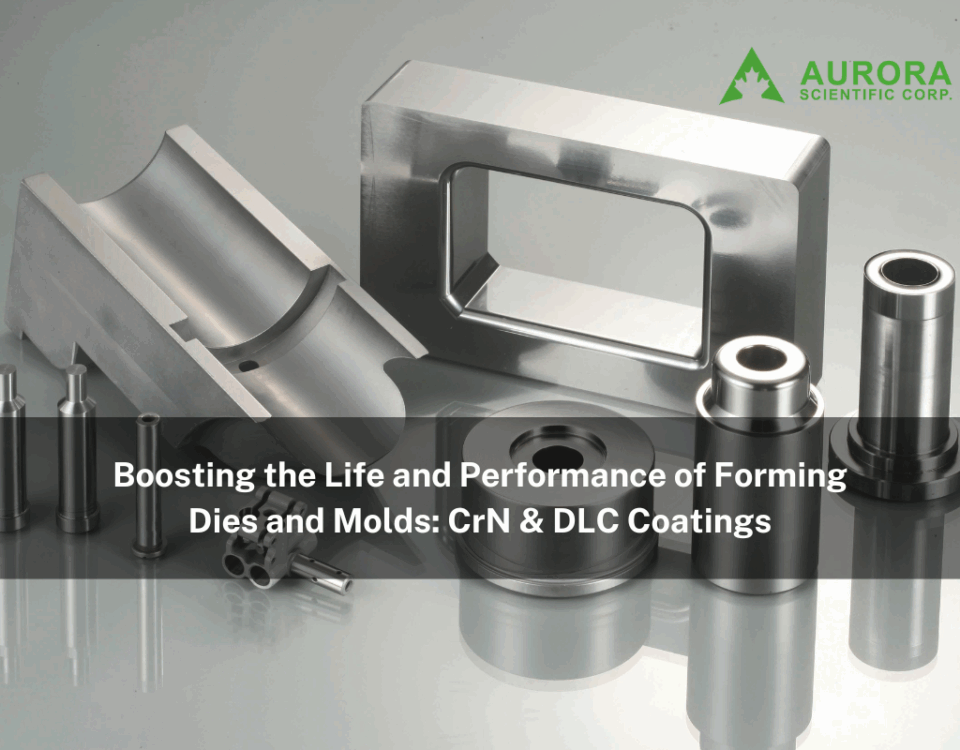

Solutions to Reduce Wear in Couplings

To enhance the durability of couplings, surface treatments are applied to increase surface hardness and wear resistance. Couplings are primarily made of high-strength steels and alloys to endure mechanical stress and harsh environments. The current market uses the following common surface treatment methods:

Induction Hardening:

A heat treatment process that increases surface hardness.

Thermal Spray Coatings:

Application of a hard metallic layer, such as tungsten carbide or nickel-based alloys, to improve wear resistance.

Aurora’s PVD Coating Solution

At Aurora, we applied our proprietary thick metal-doped Diamond like carbon (DLC) coating to protect couplings and tubes from wear damage and extend their service life. DLC coating is a carbon-based coating known for combining the desirable properties of natural diamond with the versatility of amorphous carbon. It offers a unique balance of extreme hardness, low friction, and excellent chemical resistance—making it an ideal surface treatment for components exposed to high wear and corrosive environments.

Our specialized DLC coating delivers the following key benefits:

- Reduces wear and abrasion between couplings and tubing

- Protects against chemical corrosion from crude oil and natural gas

- Features a hydrophobic surface that helps prevent tubing clogging caused by calcium carbonate hydrate formation

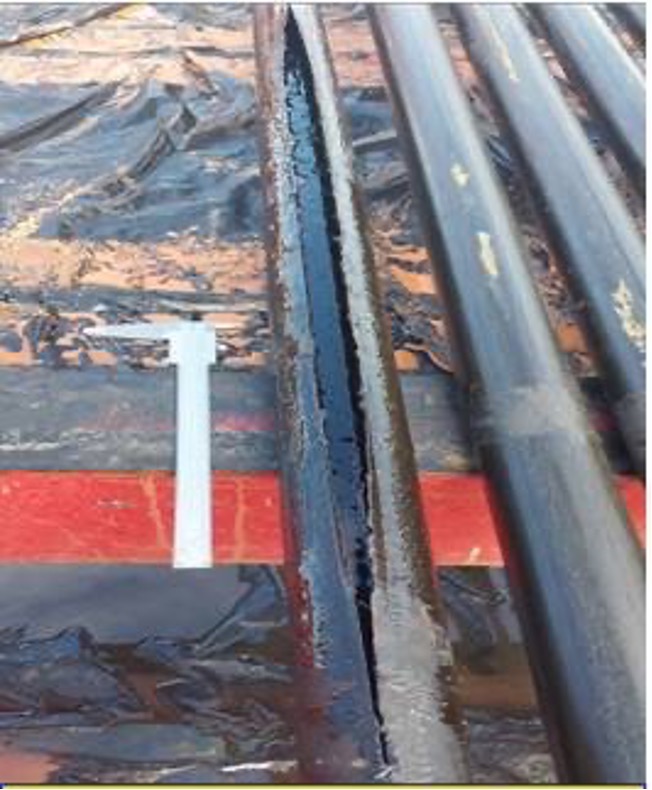

The damaged rod couplings due to the severe wear and corrosion

Broken tubing caused by the wear and abrasion against the coupling

DLC coated rod couplings by Aurora

Aurora has partnered with a major oil and gas Company in Southeast Asia to apply this thick metal-doped DLC coating on coupling and tubing. This advanced coating solution aims to improve the reliability and performance of rod pumping systems in demanding oilfield environments.

Enhance Your Products with Aurora Scientific Corp

At Aurora Scientific Corp, we specialize in high-performance PVD coatings to improve durability, wear resistance, and aesthetics. Whether you're in the aerospace, tooling, or consumer goods industry, our advanced PVD technology ensures superior protection and longevity. Contact us today to learn how our PVD coating services can elevate your products!

Contact Us

Sucker rods and couplings are essential components of artificial lift systems, particularly in rod pumping systems used in oil and gas wells. They play a crucial role in lifting crude oil from the reservoir to the surface. Couplings are threaded connectors used to join individual sucker rods into a continuous rod string. Wear occurs due to constant contact of couplings with the tubing in the repetitive motion. Especially, in corrosive well conditions, this wear is accelerated, leading to rapid material degradation and potential system failure.