August 7, 2025

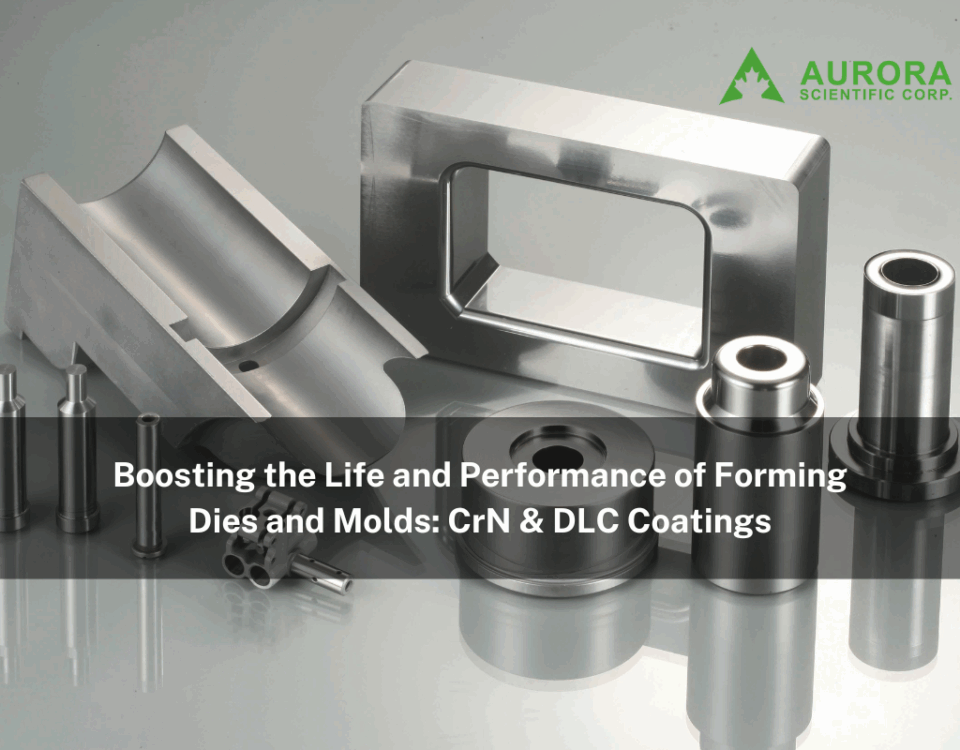

Forming dies and molds are the backbone of manufacturing — shaping metals and plastics into the parts we rely on every day. But in production, these dies and molds face tough enemies: friction, heat, and wear. Over time, these factors can shorten tool life, lower product quality, and increase costs. The solution? Advanced PVD coatings like CrN (Chromium Nitride) and DLC (Diamond-Like Carbon), which can dramatically extend die and mold life, improve part quality, and reduce maintenance.